There are many impractical units that do not really provide adequate storage for anything modern. Like the shallow closet that is built between two posts on the wall, near the floor, do not you think?. In my endless desire to create more ways to store things in my small sardine can of living space, I have decided to build this shelf unit for the bathroom.

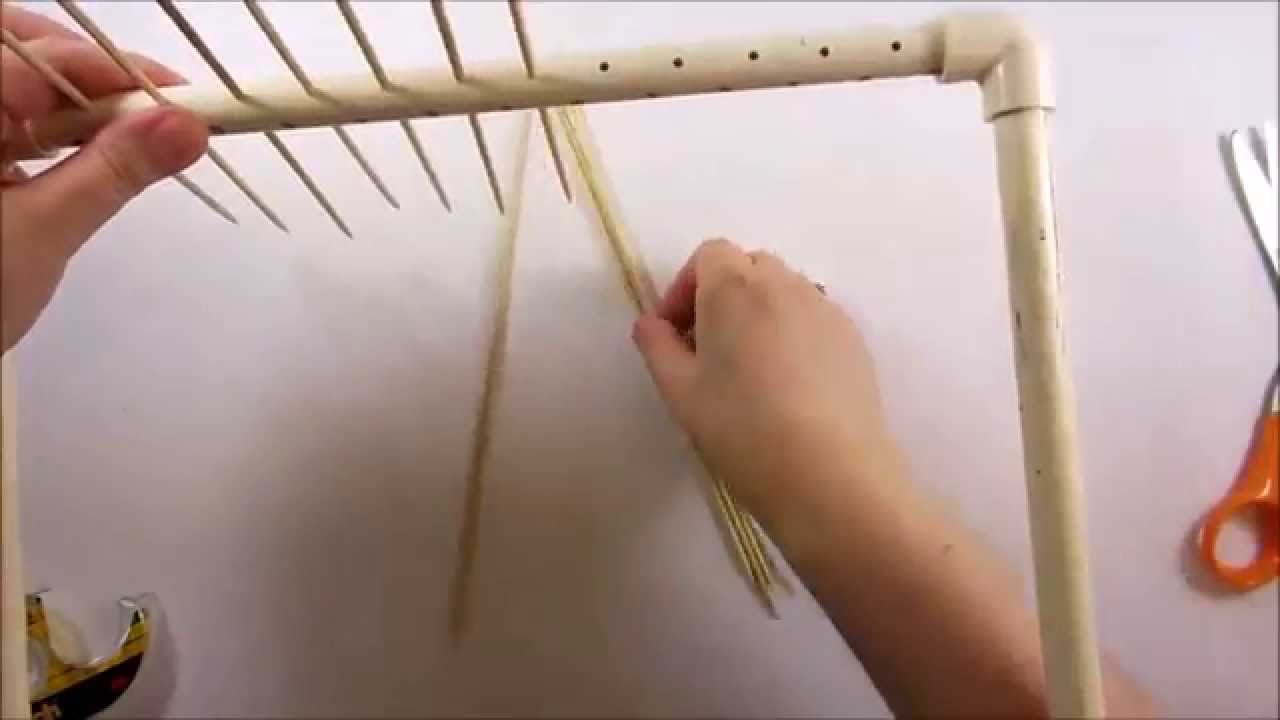

How to make a clothes rack from pvc pipe?

Working with PVC is very easy. It’s like affordable structural adjustment toys. The pipe is cheap, and you can get really cool accessories. The upper part is removable from the base and can be used as a shelf of a plant or shelf for when you leave this small place.

Step 1: Tools and materials

For this project, I used:

- Ratchet pipe cutters

- PVC chamfering and deburring tool

- Measuring tape

- Priming and cement for PVC

- (5x) PVC pipe of 10 ‘lengths of 1/2 “: The best you can get at your local hardware store

- (10x) 1/2 “PVC T-connections

- (18x) 1/2 way PVC 4-way elbows

- (4x) 1/2 “grade PVC caps

- (3x) Wood boards of 9.25 “x 24” x 3/4 “, 10 ‘of 9.25” length of poplar

- Drill and bits

- (12x) Wood screws # 6 3/4 “

- Spray to protect exterior surfaces

- Spray paint

Step 2: Make Cuts

I measured the space for which I am trying to build the shelf and came up with the design that would require the following cuts with a ratchet cutter:

- (4x) 6 “lengths for legs

- (9x) 20.75 “Long horizontal supports

- (14x) 6.125 “Long side supports

- (20x) 10.5 “For vertical side spacers

- (4x) 4 “long for the top

Step 3: Dry fit the parts

I have done a job in which I do not adjust dry or adjust the pieces, and I have cried many tears for having to do the work again. These days, I know better …

But seriously, test fit parts that are designed for close tolerances and need to go in small spaces. My original design did not compensate for the inclination of my house, so I ended up making two of the legs slightly longer.

Step 4: Stick the base

I needed the base to be solid as a rock to support the weight of the shelves and the things I plan to put on top of it.

PVC cement is very useful for this. It is very permanent and forms very strong chemical bonds. Graduation marks help maintain connections and are easily cleaned once cementing has been completed.

Step 5: Add caps

Working with PVC caps is an excellent way to make a poor quality cut polished and pleasant. In addition, it prevents water and dirt from entering the open pipe.

By adding covers to the top and bottom of the shelves, we create flat pads for the legs and completely seal the tube of possible contaminants.

Step 6: Glue the top shelves

The shelves had to be cemented along all the joints, except along the axis where the fixing screw would be inserted. The upper shelf has shorter struts with side covers.

Step 7: Make the shelves

Cutting board is easy with a cutting saw. I used a tape measure and a carpenter’s square to make sure my cuts were the correct length. If you do not have access to a cutting saw (I did not use it, I used a friend’s saw) ask the people at the shipyard to cut the wood for you. Or use the tool you choose! You have many options when it comes to making cuts in wood.

Measuring 1/2 “from the side and corners, I marked where I wanted to place the holes through which the pipe would pass. With a 1 1/4 “bit, the holes were drilled. Ideally.

Clean the plate with 220-grit sandpaper in a sanding block before sealing. I prefer to use a wood finish, it really allows the grain of the wood to shine and produce an intense natural color.

Step 8: Add the set of screws

Because someday I will have to disassemble or reuse the shelves in another configuration, I decided not to stick many of the joints and add fixing screws.

I added fixing screws along the vertical axis of the 4-way joints by drilling a hole through the fitting and the pipe, then added a 5/8 “wood screw.

Step 9: Painting the PVC

PVC paint requires spray paint designed to adhere to the plastic. Plastic paint used to come in a very limited number of colors, but now it looks like it can get all the shades of the rainbow.

I prepared the entire surface of the pipe and joints to be painted with 220 grit sandpaper and then wiped with a cloth.

I waited 20 minutes between layers and rotations.

If you need to retouch the paint after more than a few hours have passed since the last, it is best to wait 48-72 hours to reapply, the base coat may flake.

Step 10: Reassembly

Reassembly happens level by level. Going back to the holes takes a few minutes and hitting the pieces in place with a deadly hammer will require some muscle.

Insert the fixing screw and slide the shelves between the layers so that the shelf is anchored in the pipe fitting.

The tolerance of the pipe fitting is not designed to compensate for some layers of spray paint. So, clean the tip of the pipe and the inside of the joint with a little fat on a towel so that the pieces slide more easily.

This shelf fits perfectly in my crazy little house and helps me keep my bathroom more organized.

Average Rating